Late May 2017 – On a sunny Sunday, I spied a shiny black beetle at the side of a path whilst hiking in the Heritage Grove Redwoods, La Honda, California. I realized instantly that this bug would make a perfect model for a ceramic insect that I would coat with some recently-purchased Black Luster overglaze.

Luckily, my hiking partner had his iPhone and took this Photo.

Luckily, my hiking partner had his iPhone and took this Photo.

Research revealed that this creature has the fantastic name of Darkling Beetle.

I sketched what I had in mind for making a ceramic bug.

I sketched what I had in mind for making a ceramic bug.

My idea was to make antennae and legs from wire leftover from my hobby of making earrings, using wire-wrapping techniques learned back then.

The bugs would be mounted on driftwood collected from the beach earlier in the year after a gigantic storm.

Copper tacks from my late-father’s stash of hardware would be perfect for attaching the bugs to the driftwood.

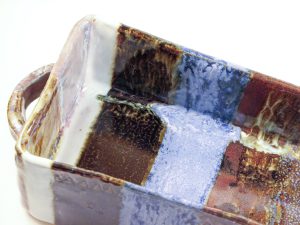

I hand-built 6 experimental bugs out of high-fire stoneware clay. Each started as a closed pinch pot. Different features were added, such as up-lifted flared wings, bugged eyes, mouth/lips. I made protruding eyebrows and sled feet, with holes to accommodate the later addition of wire antennae and legs.

After the bugs dried, I applied various combinations of underglaze colors for highlighting different features. All bugs survived the bisque firing.

For glazing, I experimented with various glossy glazes, including Palladium (Silvery Black), Saturation Gold, Pansy Purple, and Transparent.

After the glaze firing, the bugs needed enhancement with Luster overglazes. Lusters contain precious metal elements, such as real gold, which give a glittery and/or iridescent effect. For most of the bugs, Black Luster was used to make their bodies shinier, and to highlight their wings. Opal Luster was applied to wings (including underneath). Gold Luster was applied to lips, eyes, and/or to highlight the tips of wings. The pieces were re-fired at Cone 020 (1180 F), with the end result being a shimmery finish, gorgeous to look at.

Created 2 antennae and 6 legs from gold wire which was threaded through holes in each bug, coiled with pliers. The last step — no small effort — was to wrestle the bugs onto their driftwood mounts using vintage copper tacks.

December 2017 (6+ months later) — The inspiration of seeing a little black beetle evolved in my brain and hands into totally unique and eye-catching fantastical art pieces. Also appropriate for older children interested in insects — adorable companions or a great addition to a bug collection.

Each one measures approx. 2+″ x 3+” x 2+″

Listed for Sale on Etsy.com, click on LegalizePotteryShop.